Make/Shift

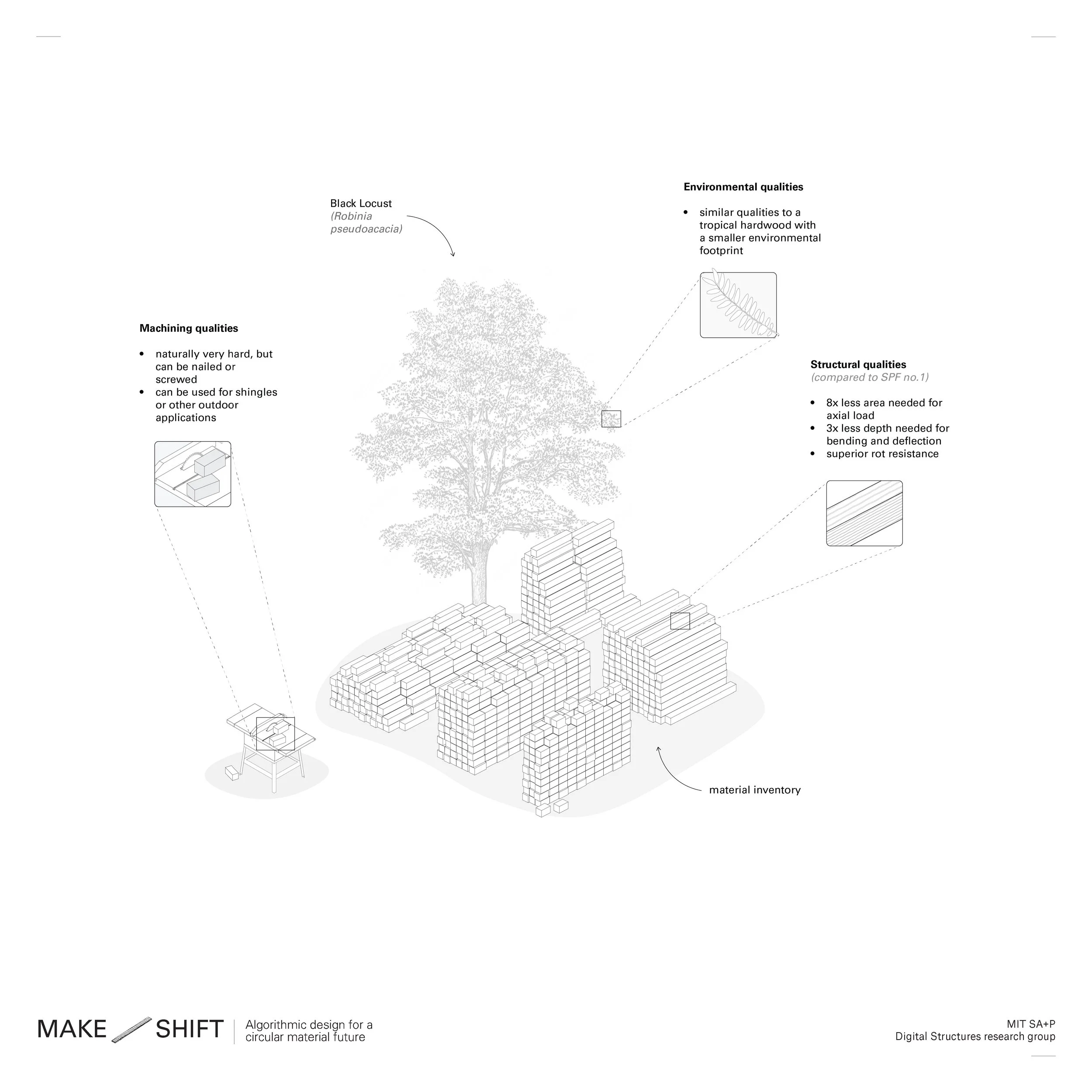

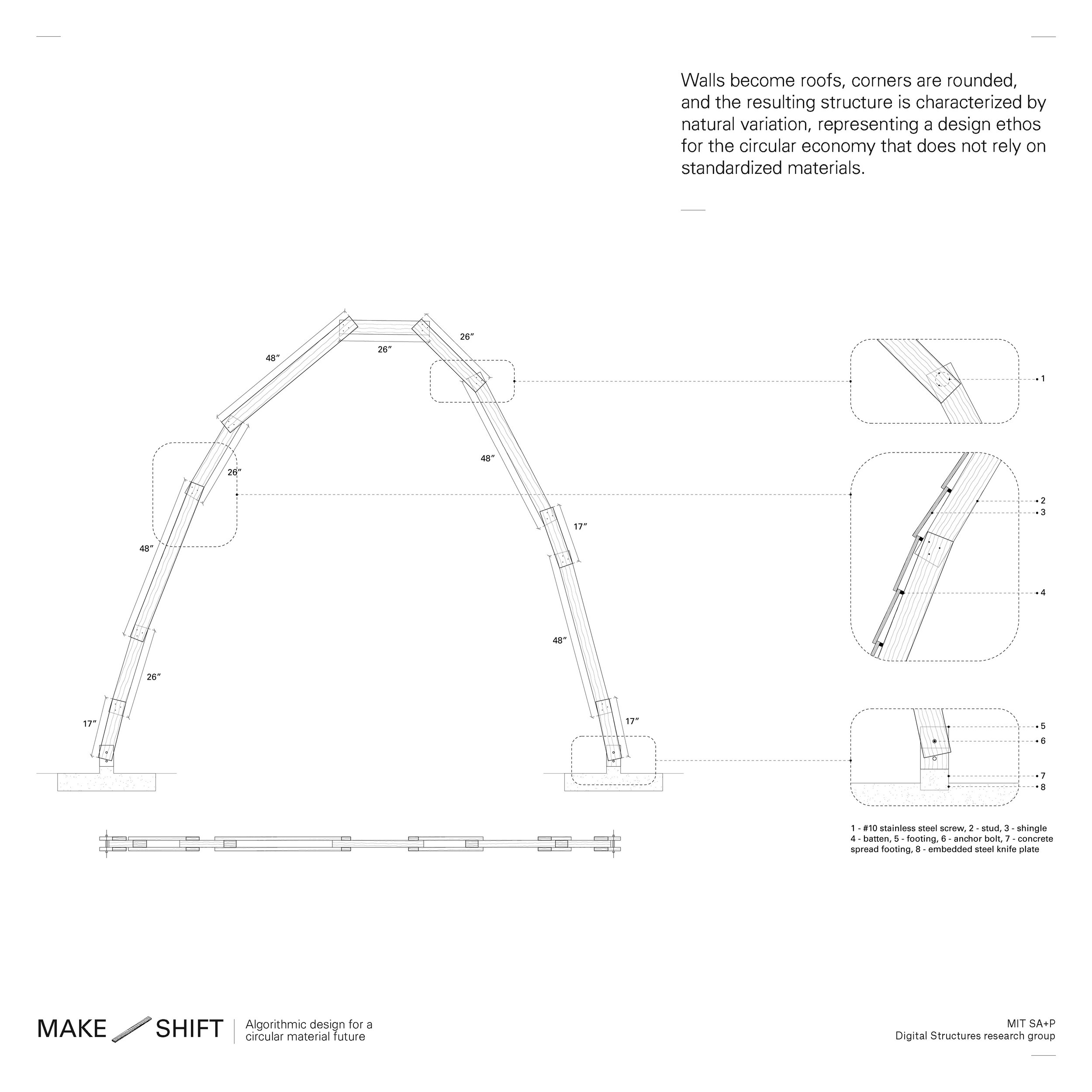

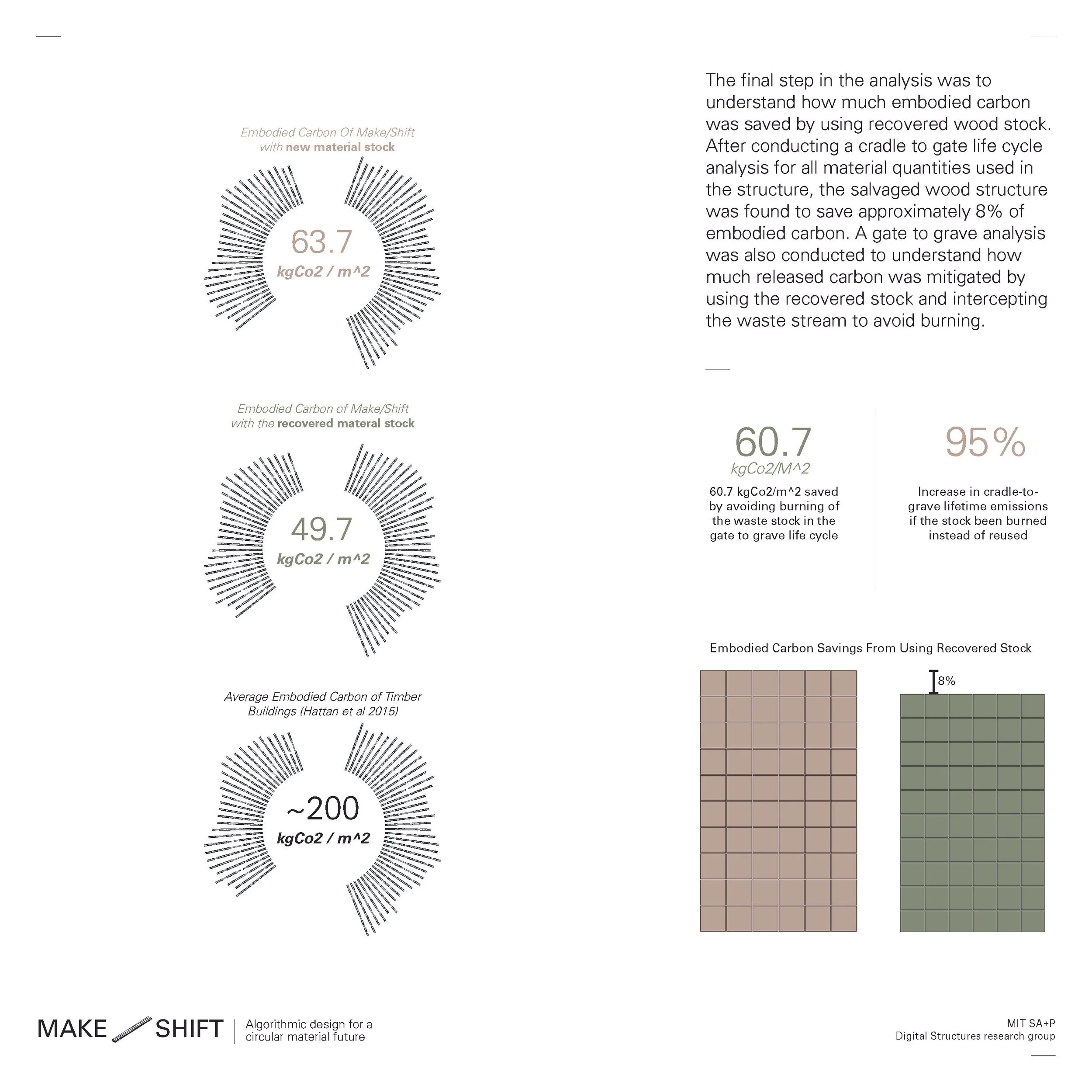

Make/Shift proposes a system that takes advantage of the non-standard lengths of the recovered wood stock to defy orthogonal norms and create a structural system that embraces variability and flexibility, enclosing a space for storing second-life materials and hosting educational workshops. Design strategies with dimensional lumber rely on long pieces, complex joints, and don’t always use the elements optimally , often compressing them against their grain rather than along it. Instead of forcing unconventional building materials into status- quo forms and assemblies, Make/Shift proposes a system that takes advantage of the non-standard lengths of the recovered stock to defy orthogonal norms and create a structural system that embraces variability and flexibility, enclosing a space for storing second-life materials and hosting educational workshops.

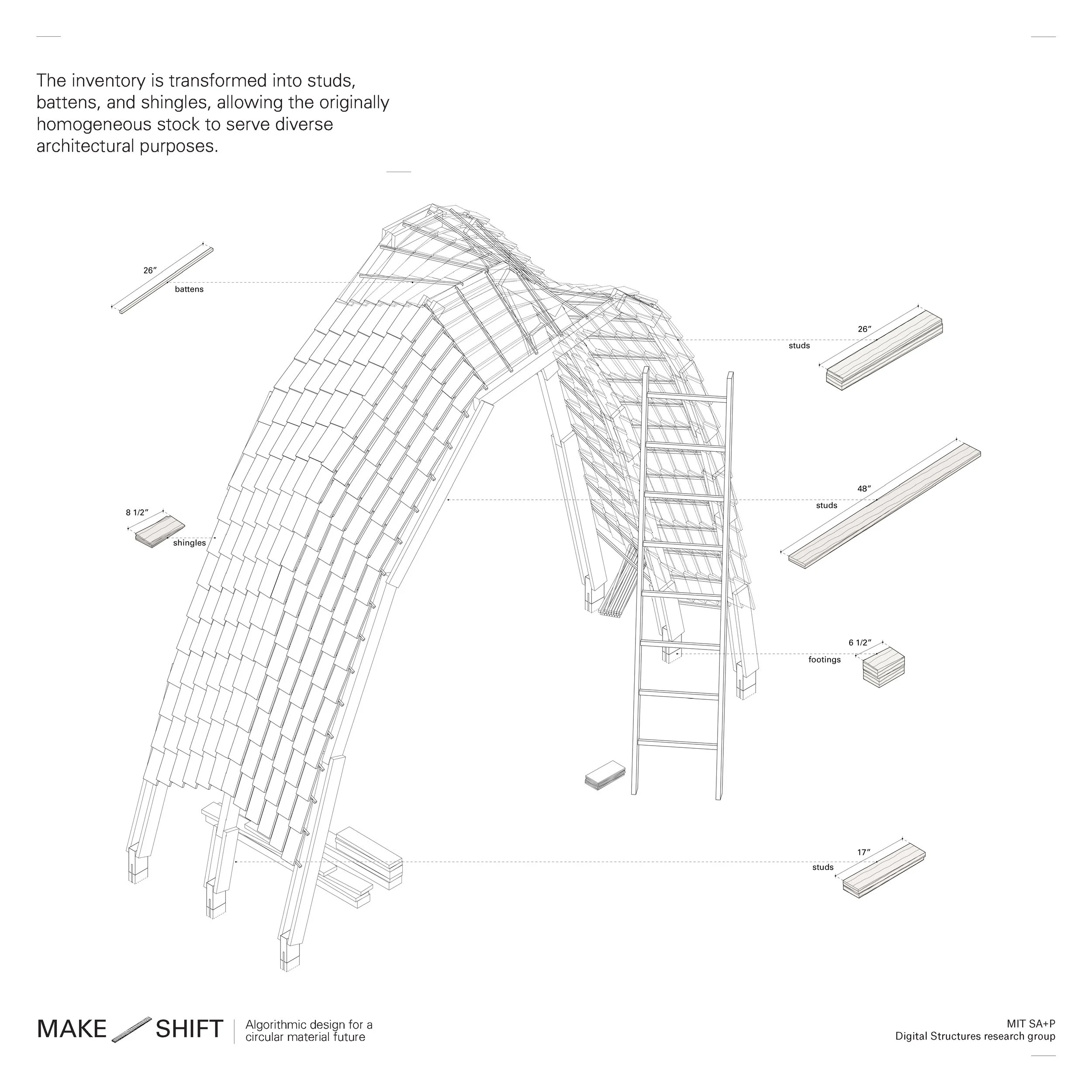

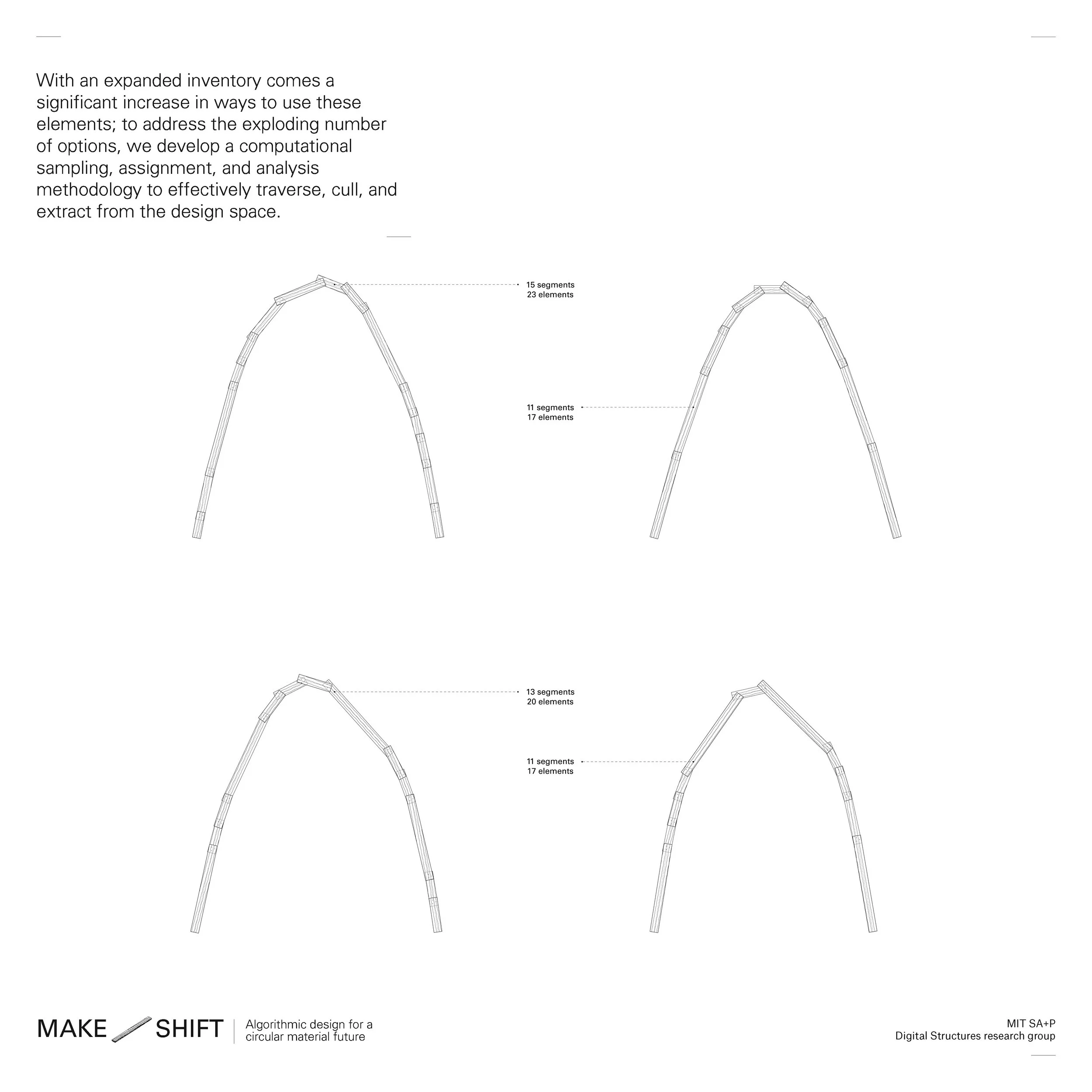

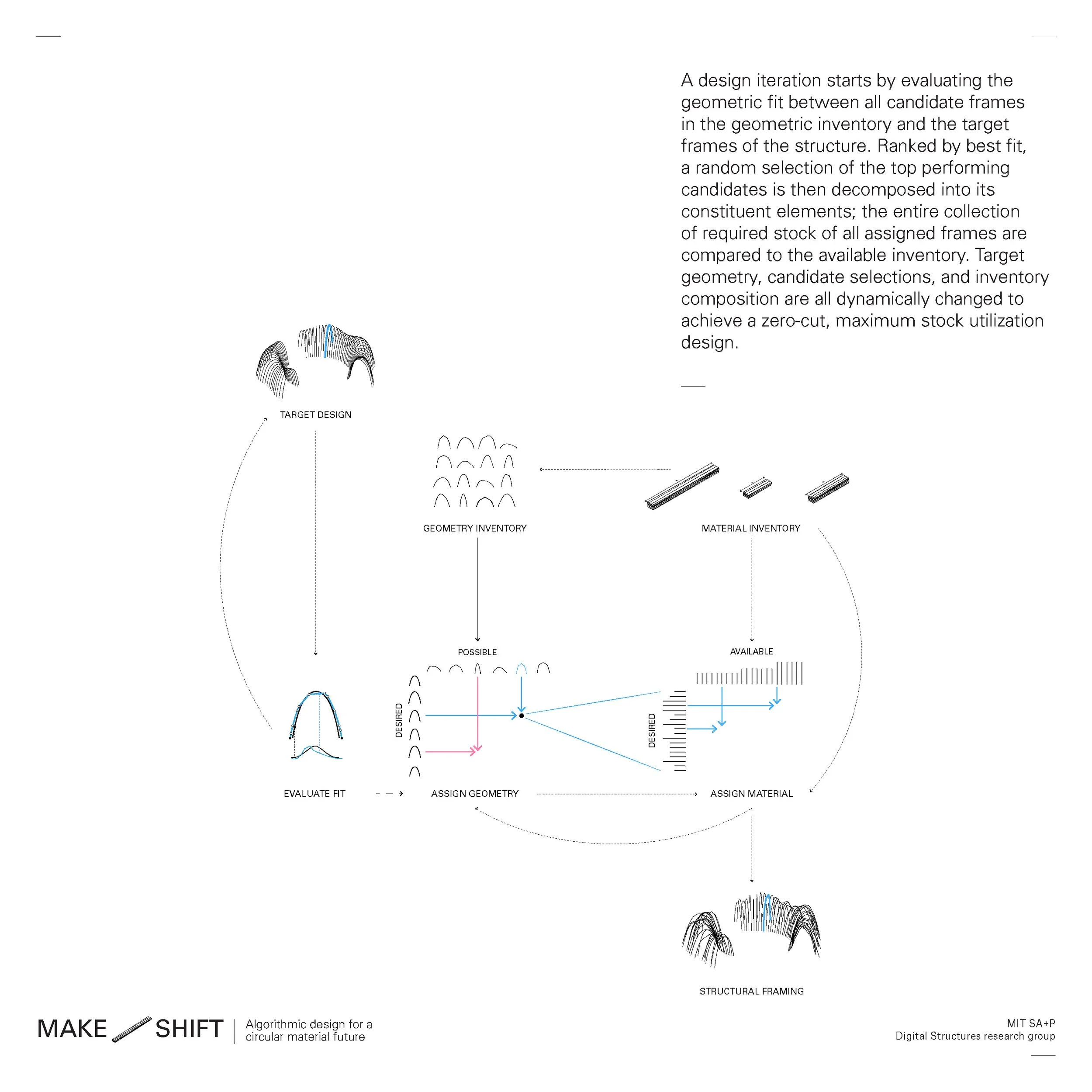

The inventory is transformed into studs, battens, and shingles, allowing the originally homogeneous stock to serve diverse architectural purposes. To form the building structure and envelope, we break from the standards of conventional stick-framing: multi-part “stud” frames are nailed together and transformed into arches, battens are forced out of horizontal alignment due to the set lengths of the stock pieces, and shingles register the underlying variation on the exterior.

This project was shortlisted for a design competition.

Team: Kiley Feickert, Keith J. Lee, Inge Donovan, Jenna Schnitzler, Juliana Berglund-Brown, and Caitlin Mueller