Reusing Heavy-Section Steel in Buildings: Carbon Reduction Potential and Material Availability

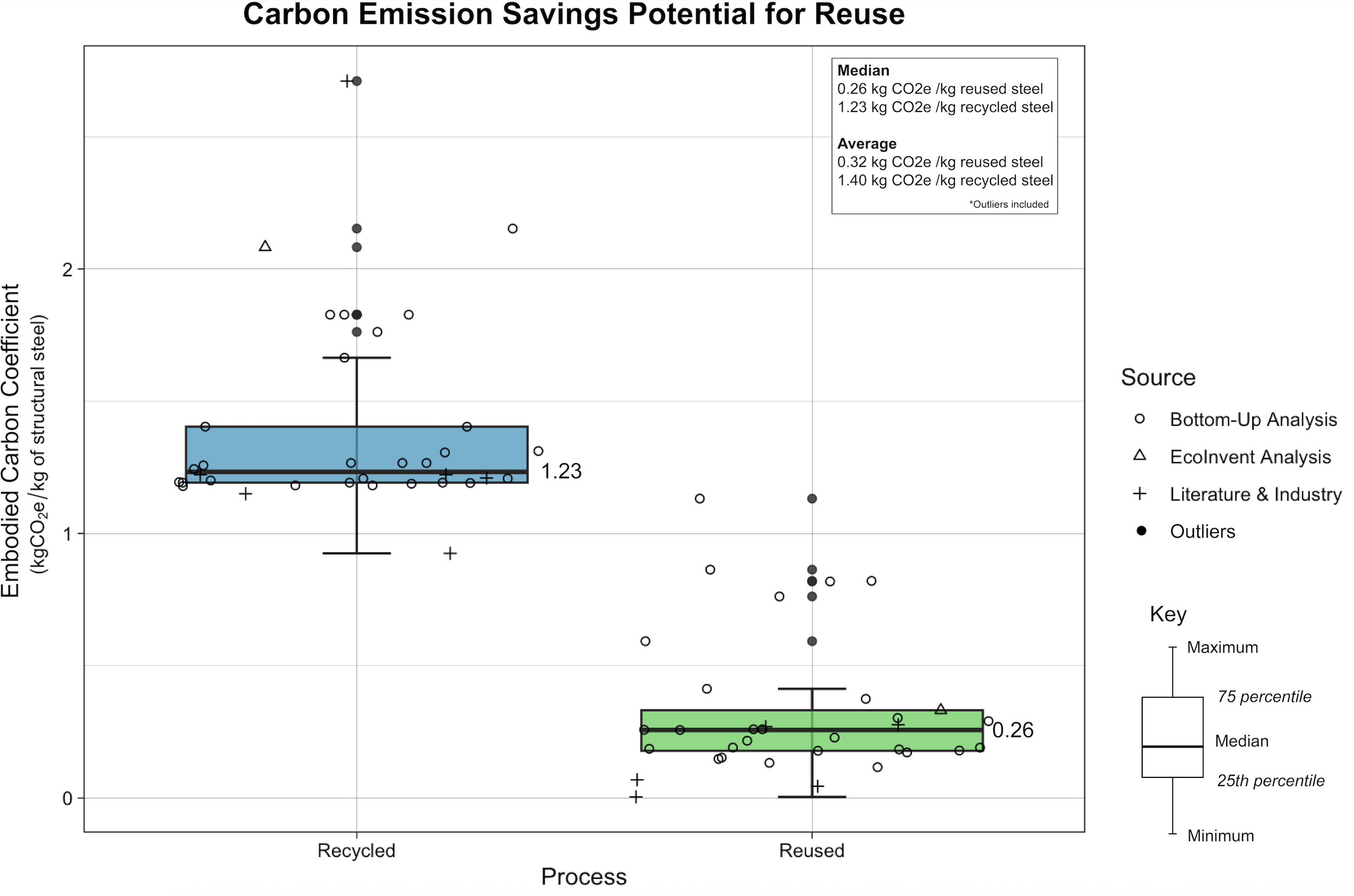

Designing with salvaged structural steel is a beneficial alternative for structural engineers to reduce embodied carbon in the built environment. However, there are still many regulatory and sectoral barriers to reusing hot-rolled steel sections in buildings at scale, including establishing its embodied impact reduction potential and minimizing the uncertainty regarding element availability. This paper first contextualizes structural steel and steel scrap supply chains throughout building construction and use. Next, a carbon equivalent analysis of reused steel and recycled steel was carried out, which considered the life cycle phases included in Environmental Product Declarations. These quantities were then amalgamated with industry and literature values and assessed for varying parameters, including geometric characteristics, transportation distances, and electric grid factors. From a cutoff, bottom-up life-cycle analysis, a 60%–83% reduction in greenhouse gas emissions was estimated from steel reuse instead of recycling, depending on the element and project. A high-level material flow analysis was conducted for the structural steel market in the United States, which indicated at its upper bound that the quantity of the existing steel heavy-section scrap could cover 80% of total consumed heavy-section steel and 140% of heavy-section imports. In short, this paper demonstrates the intrinsic carbon reduction value and scaling potential of steel reuse.

J. Berglund-Brown, and J. Ochsendorf, “Reusing Heavy-Section Steel in Buildings: Carbon Reduction Potential and Material Availability,” Journal of Architectural Engineering, vol. 31, no. 2, p. 04025020, Jun. 2025, doi: 10.1061/JAEIED.AEENG-1918.